On the afternoon of Saturday 25th August Project Merlot spent a couple of hours on a 2 post lift in the workshops of EMG Motor Group where Team Merlot set to work fitting a new set of front brake discs (supplied by EMG), Front & rear Axxis Ultimate pads and Front & rear Flyin' Miata adjustable anti-roll bars (supplied by Performance 5). This was all in preparation for it's track day at Cadwell Park on the following Wednesday organised by Javelin Track Days.

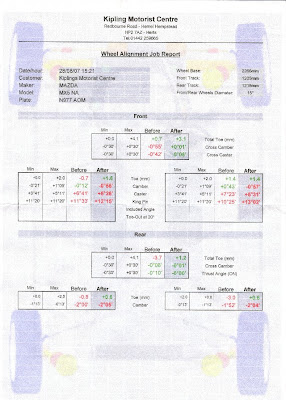

At extremely short notice the Merlot was squeezed into a spare time slot with Wheels Inmotion for a full geometry check and adjustment. After discussing with Tony our requirements for the little "racer" he proceeded to dial in the desired amount of caster, camber & toe-in ensuring the car would be predictable and controllable for any ability of driver who maybe behind the wheel.

At extremely short notice the Merlot was squeezed into a spare time slot with Wheels Inmotion for a full geometry check and adjustment. After discussing with Tony our requirements for the little "racer" he proceeded to dial in the desired amount of caster, camber & toe-in ensuring the car would be predictable and controllable for any ability of driver who maybe behind the wheel.

At extremely short notice the Merlot was squeezed into a spare time slot with Wheels Inmotion for a full geometry check and adjustment. After discussing with Tony our requirements for the little "racer" he proceeded to dial in the desired amount of caster, camber & toe-in ensuring the car would be predictable and controllable for any ability of driver who maybe behind the wheel.

At extremely short notice the Merlot was squeezed into a spare time slot with Wheels Inmotion for a full geometry check and adjustment. After discussing with Tony our requirements for the little "racer" he proceeded to dial in the desired amount of caster, camber & toe-in ensuring the car would be predictable and controllable for any ability of driver who maybe behind the wheel.

1 comment:

When we talk about chassis dynamics we often talk about a car chassis as though it’s a singular thing, but actually when trying to think about technical aspects of either driving a chassis or it’s design that’s incorrect and unhelpful.

The car chassis is in reality just a collective term for a group of independent mechanical sub-systems. Most people are of course just interested in the driving so are only concerned with the net result of all of the sub-systems performing together as one. The unfortunate effect is that this makes it quite hard for these people to explain themselves clearly when talking to technical engineers who are in place to change the chassis set-up to suit them.

Understanding each and every one of the individual sub systems certainly does go a very long way to help in understanding exactly how a car chassis works, but understanding how all of these sub-systems interact with one another really is the Holy Grail of chassis dynamics.

So if we begin to think of the chassis in fact just as a complicated mechanical system we can take a look at other mechanical systems in general and start to apply the universal sciences and truths involved in systems engineering.

To avoid going into a great deal of depth talking about harmonics I think it’s best now if we can just except for the time being that systems have a natural frequency (actually they have more than one, that’s a discussion for another time) and that these natural frequencies of the system are determined by the systems stiffness.

The primary frequency of a car chassis will normally be very low and measured in Hertz or Hz for short, this description is historically used in science to indicate cycles per second.

Ok now for the bit we actually care about, the effect of the chassis’s primary natural frequency. In real life this frequency dictates the minimum level of chassis correction or inputs per second required from the driver in order for the car to stay on its intended path.

For example:

A Rolls Royce might typically be set-up with a natural frequency of around 0.65hz, meaning that you can be very lazy when driving this car and it will still follow it's prescribed path.

A Mitsubishi Lancer EVO which is fairly typical of the aggressive sports saloon car market, might have a natural frequency of around 1.8hz meaning that the driver must give inputs at a rate of just under 2 adjustments per second, that’s quite a work rate.

In the extreme a formula 1 car is typically set at 4.5-4.8hz frequency, that’s a MINIMUM of almost 5 adjustments per second!

Post a Comment